Marian / BrightView Application Guide

Material Selection & Converting

BrightView’s computational optics film solutions offer superior LED hiding, brightness, and efficiency in an increasingly smaller form factor. These films replace thick and bulky plastic diffusers to allow for further customization. Partnered with Marian’s expertise in custom, precision die-cut components and multi-layer lamination capabilities, we deliver high quality, innovative solutions tackling our customers unique engineering challenges.

Optics & Material Selection

Why Computational Optics?

Computational Optics are micro lens structures, that shape light at the micron level to create complex, unique outputs while maintaining efficiency and aesthetic uniformity.

Optics Selection

Both off-the-shelf and custom computational optics films are available to support the specifications needed for your application. The micro lens structures will often depend on the desired outcome (uniformity, light shaping, increased brightness) and the constraints and parameters of the project. For more information on optical properties and applications, click here.

Substrate Selection - PET vs. Polycarbonate

BrightView optics are written on two main substrates: PET and Polycarbonate. PET is a thinner, and more cost-effective option while polycarbonate is the more durable option. Polycarbonate is often used in applications like vehicles and displays due to its better performance on key temperature metrics.

Converting Info & FAQs

Marian Converting Info

Marian is a global leader in providing precision die-cut component parts for customers in the consumer electronics, automotive, and medical industries. With over 1,500,000 square feet of production space worldwide and state-of-the-art manufacturing technologies, Marian engineers work closely with customers to solve complex manufacturing and assembly problems.

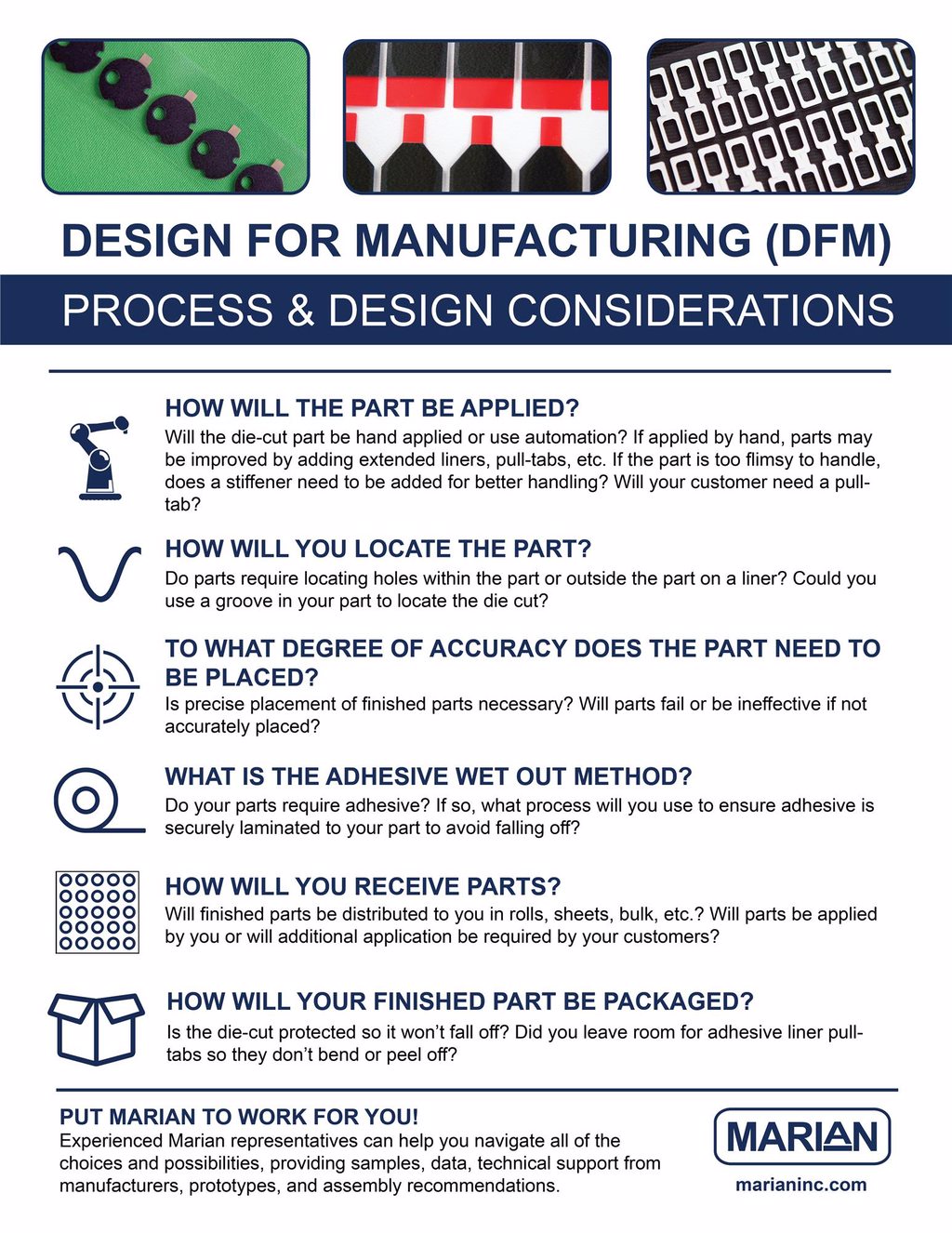

Design for Manufacturing (DFM) is an important part of Marian’s capabilities and something that truly separates us from our competitors. We’re not only concerned with manufacturing the best parts for our customers’ applications. We also aim to design and provide those parts the way that makes sense for your processes.

Converting FAQs

Q#1: How fast can I get parts? What is your turnaround time?

A: Speed, predictability, and reliability are paramount to Marian. Lead times for prototypes, production releases, new tooling, and first articles will vary based on the materials and type of manufacturing required. Marian keeps millions of dollars in raw material on hand which significantly reduces lead times. We respond individually and quickly to customer requests for speed, so please reach out and let us know your needs and circumstances.

Q#2: I am developing a new product/program. Can Marian help me with prototype needs before production?

A: Marian often uses CAD cutting technology to quickly and efficiently produce prototype parts without the cost and time required for hard tooling. Creating prototypes with lasers, blade-cutting-plotters, and water-jet cutting makes it easier and less expensive for you to make adjustments to your design.

Q#3: Does Marian have any quality certifications?

A: Yes, all of Marian’s global locations (13) are minimally ISO 9001 certified. However, some carry additional certifications which could include IATF, ITAR 16949 , ISO 140001, AS9100, ISO 13485 and others.

Download the full PDF application guide below!